Modern Beverage Production Line: The Optimal Solution for Performance and Quality Optimization in the Food Industry

In the context of increasing beverage consumption demand, investing in modern production systems not only helps businesses increase productivity but also reduces costs and enhances market competitiveness.

I. The Strategic Importance of Beverage Production Lines

Production lines play a fundamental role in the manufacturing process of goods and services across many industries, particularly in the food and beverage sector. A production line is defined as a set of work steps established in a logical sequence at a factory. Each step in this chain holds significant importance, creating harmony and continuity to transform raw materials into final products. Through the connection of modern machinery, meticulous processes, and smart equipment, production lines deliver optimized performance and quality. This system not only ensures efficient mass production but also creates high consistency in product quality. Production lines are especially effective when manufacturing or processing large quantities of a single item, helping businesses manage processes efficiently and deliver the highest quality products to the market.

In the context of continuously evolving technology, many businesses have transitioned to using automation to increase the number of products passing through production systems. Automation is seen as the key to improving productivity across many industries, allowing businesses to maximize employee potential. For the beverage production industry, implementing automation brings significant benefits such as increased processing speed, enhanced flexibility to produce more product sizes, improved finished product quality, and increased system reliability through online diagnostics and the Internet of Things (IoT). Investing in modern beverage production equipment is an important strategic decision for any production line, especially as consumer preferences become more diverse and demand for varied beverage options continues to grow.

The concept of an “optimal solution” in beverage production isn’t merely about applying the most modern technology. It’s the harmonious combination of advanced technology, standardized production processes, efficient management systems, and strict compliance with quality and safety standards. This includes selecting production lines suitable for business scale, specific product types, input water characteristics, and financial capacity, aiming to achieve the highest performance, quality, and safety at the most reasonable cost.

Technological development has changed how we perceive production “lines.” Initially, a production line was understood as a sequence of consecutive work steps linking independently operating machines. However, with the advent of automation, smart devices, PLC and HMI control systems, along with IoT connectivity, production lines have evolved into integrated production ecosystems. In this ecosystem, components not only operate in sequence but are also connected, controlled, and managed centrally, where data is shared and processes are synchronized to optimize the entire system. This means investors and managers need comprehensive investment and management strategies, not just focusing on purchasing individual machines or optimizing independent processes. Instead, they must consider integration capabilities, compatibility, and synchronization between equipment and software. The ultimate goal is to optimize the performance of the entire system, not just individual elements, thereby delivering superior efficiency and greater adaptability for businesses.

See also: Air compressorsII. Superior Benefits of Automated and Modern Beverage Production Lines

Implementing automated and modern beverage production lines brings numerous strategic benefits, helping businesses enhance their competitive position and achieve sustainable growth.

Enhanced productivity and operational efficiency

- Production lines automate manufacturing processes, minimizing human intervention and significantly increasing production speed. Machinery systems operate smoothly with clearly assigned tasks, helping avoid unnecessary errors.

- The operating speed of automated production lines is many times faster than manual human operations, enabling factories to clearly improve production output.

- Installing industrial production lines not only liberates labor but also optimizes operating time, maximally reducing the cycle time of each process.

- Automation is key to improving productivity, increasing processing speed, and adding flexibility for multiple product sizes.

- Furthermore, machines are designed and programmed with high precision, enabling continuous production operations with minimal downtime, optimizing both time and costs.

Improved product quality and consistency

- Automated production lines are uniformly designed and controlled, ensuring product quality and increasing consistency. Businesses can more carefully monitor production processes, making it easier to identify and resolve potential issues.

- Using modern machinery helps precisely control technical parameters, minimizing errors and product defects.

- Products always maintain the highest uniformity with low defect rates, meaning reduced material costs and production expenses related to error correction or compensation production.

- Particularly, automatic filling systems ensure accuracy and uniform measurement while providing flexibility when changing bottling requirements.

Cost optimization: Reduced labor, material, and operational costs

- Production lines significantly save labor costs by reducing the number of required workers.

- Using modern equipment also helps businesses save materials, energy, and maintenance costs.

- Employing automatic filling lines helps companies save costs by reducing error rates during production and avoiding waste.

- Automation helps businesses reduce various costs, enabling high-yield production while lowering per-unit production costs, resulting in cheaper product prices and enhanced competitiveness.

- Although initial costs for automated production lines may be high, this is considered a smart and effective long-term investment.

When evaluating investments in automated production lines, decision-makers need to apply long-term thinking. Rather than focusing solely on initial procurement costs, they should calculate Total Cost of Ownership (TCO) and analyze the overall economic benefits the production line brings throughout its operational lifecycle. The initial investment isn’t merely an expense but a financial lever to optimize the entire production value chain. By minimizing waste (materials, waiting time) and maximizing output within the same timeframe, businesses can achieve higher profit margins and faster capital recovery. This is particularly important in the food industry where price competition and production efficiency are extremely intense.

See also: Air compressor accessoriesEnsuring labor safety and food hygiene

- Production lines are designed with safety measures that minimize occupational accident risks for workers.

- Automation systems help eliminate hazardous, toxic tasks, ensuring a safe working environment for laborers.

- Regular equipment cleaning and process compliance are necessary to ensure food hygiene safety.

- It’s crucial to ensure production lines comply with quality safety standards and strictly implement quality management systems.

Enhanced competitiveness and market adaptability

- Businesses adopting production lines have clear advantages in productivity, product quality, production costs, and labor safety compared to non-adopting enterprises.

- This helps enhance market competitiveness, attract customers, and increase business revenue.

- Automation also provides maximum production flexibility, allowing businesses to quickly adjust to meet market demands.

- Automatic filling machines easily integrate into smart automated packaging lines, aligning with automation trends to build advanced factories.

The relationship between automation, product quality, and workforce upskilling forms a positive cycle. Automation doesn’t merely replace labor but also promotes workforce specialization and skill upgrades. When workers are trained to operate and monitor automated systems, they gain capabilities to identify and resolve more complex problems, thereby maintaining and continuously improving product quality. This means investing in automation isn’t just an equipment expenditure but also a human capital investment. Businesses need accompanying personnel training and development strategies to maximize benefits. This not only creates higher-quality products but also builds a competent workforce ready to adapt to future technological advancements, delivering sustainable competitive advantages.

Table 1: Comparison of Benefits Between Automated Production Lines vs Manual/Semi-Automatic

| Criteria | Automated Line | Manual/Semi-Automatic |

|---|---|---|

| Product quantity | Mass, batch production | Single-piece, small quantity production |

| Product uniformity | Identical products, high consistency | Unique, customized products |

| Production time | Fast, continuous | Slower, time-consuming |

| Production cost per unit | Low cost due to mass production | Higher cost due to individual production, labor-intensive |

| Automation level | Uses multiple machines, automation technology | Primarily manual or semi-manual |

| Flexibility | Less flexible (hard to change after setup) | Highly flexible, easily adjustable to customer requirements |

| Technical requirements/Initial investment | Large initial investment in machinery | Requires skilled workers and high technical expertise |

| Labor safety | Ensures safety, eliminates hazardous work | Higher accident risk |

| Product quality | High quality, few defects | Inconsistent quality, prone to errors |

| Competitiveness | Enhances market competitive position | Lower competitiveness |

III. Classification and Applications of Common Beverage Production Lines

The beverage industry is highly diverse, and each product type typically requires a production line with specific equipment and processes to ensure quality and efficiency.

Purified and bottled water production lines

- This line’s primary application is producing bottled drinking water, large containers, and direct drinking water.

- The water filtration system typically uses large-capacity RO (Reverse Osmosis) technology combined with sterilization methods like ultraviolet (UV) or ozone. RO technology can remove 90-98% of TDS (Total Dissolved Solids) content and eliminate bacteria, viruses, and heavy metals, producing ultra-clean, purified water.

- Finished water products processed through this system must meet quality standards for direct drinking water (6-1:2010/BYT) from the Ministry of Health.

- For PET bottles, the process typically includes preparing caps and bottles. PET bottles are usually new products, not reused like 20L containers, so they only need rinsing before filling.

- The bottles are then fed into automatic water filling and capping systems. The next stage is quality inspection (QC), printing expiration dates on caps, applying labels to bottle bodies or necks, heat-shrinking, and finally packing finished products into boxes for storage.

Carbonated beverage production lines

- This is a modern equipment system used to produce various carbonated drinks, including soft drinks, soda, and carbonated fruit juices. The line is designed with high automation levels, ensuring quality and food safety throughout the process.

- Common production process includes:

- Water purification: Input water sources (usually from wells) are processed through coarse filtration systems, then sand filters to remove fine particles. Water is chlorinated and then filtered through activated carbon to remove residual chlorine and organic matter. A vacuum pump removes gases from water before it enters the dosing station.

- Heating and ingredient mixing: Prepares ingredients like sugar and water. For fruit syrups, pasteurization is typically applied. Water and syrup are carefully combined through a precise balancing machine to create a complete mixture. Mixers are designed with modern technology, ensuring even mixing cycles and precise execution.

- CO2 saturation: This process injects food-grade pure liquid CO2 into carbonated beverages, reaching concentrations specified by technical requirements. This process enhances digestive effectiveness and extends product shelf life.

- Filling and packaging: Bottles or cans are prepared (rinsed with clean water if new, or thoroughly cleaned if reused). Products are then filled into bottles using automatic filling machines. For carbonated drinks, isobaric filling principles are applied where CO2 is injected into bottles until internal pressure balances with tank pressure, then liquid flows in using height differential. Finally, products are capped and transferred to final packaging stages.

Fruit juice, tea, and herbal beverage production lines

- This line specializes in producing tea and herbal beverages, as well as fresh or concentrated fruit juices. Juice processing includes multiple stages like cleaning, selection, spraying, inspection, heating, juicing, filtering, clarifying, using filters, conversion, sterilization, aseptic filling, passing through sterilization tunnels, cooling, drying, and packaging.

- Main components include water treatment systems, mixing and heating systems, CIP (Clean-in-Place) cleaning systems to ensure hygiene, filling machines, sterilization systems, dryers, date printers, packaging equipment, and product conveyors.

- Line capacity can be customized per customer requirements, ranging from 2,000 to 36,000 bottles per hour. Various sterilization methods are applied like Pasteurization, heat sterilization, or UHT (Ultra High Temperature) to ensure safety and extend product shelf life. The entire production process is typically automatically controlled by PLC systems, saving labor and enabling effective production management.

Differences between mass production and made-to-order production

- In manufacturing, there are two main methods: assembly line (mass production) and custom production. Assembly line production suits large-volume, batch production of identical products, ensuring quality and design consistency, with low per-unit costs due to automated, continuous processes. The beverage industry is a typical assembly line application.

- Conversely, custom production suits unique products tailored to customer requirements in small quantities. This method is typically slower and more expensive as it’s primarily manual or semi-manual.

- Product diversification in the beverage industry requires high flexibility in line design. Different production lines (purified water, carbonated, juice, tea) have specific processes and equipment. However, modern systems can also change bottle types or fill different products on the same machine (e.g., mineral water, cooking oil, soy sauce). This shows modern beverage manufacturers need not just efficient lines for single products but also adaptability to diversify product portfolios, meeting increasingly volatile market demands. When planning investments, businesses should consider modular, easily upgradable or adjustable lines to produce different beverages or change packaging sizes. This optimizes initial investment capital, minimizes risks when market trends change, and enables faster response to new opportunities, enhancing overall competitiveness.

IV. Structure and Technological Process of Optimized Beverage Production Lines

An optimized beverage production line consists of multiple specialized systems and equipment working synchronously under strict technological processes to ensure performance, quality, and product safety.

A. Main Components and Equipment

- Industrial RO water treatment system:

- Operating principle: RO (Reverse Osmosis) uses reverse osmosis where water moves from high concentration (more impurities) through a semi-permeable membrane to low concentration (fewer impurities) under pressure. RO membranes have microscopic pores allowing only water molecules through, retaining 90-98% of TDS (Total Dissolved Solids), bacteria, viruses, and heavy metals.

- Basic structure: Includes heavy metal removal (multi-layer filtration with sand, gravel, ODM particles, manganese, Filox), color/odor adsorption (activated carbon), water softeners (removing Ca2+, Mg2+ to prevent membrane clogging), precision filters (removing ~5 micron impurities), RO membrane (the system’s heart, removing up to 99.99% dissolved solids), and microbial sterilization modules (UV, ozone) to prevent bacterial regrowth in pipes.

- Importance: Ensuring input water meets food safety hygiene standards is fundamental for final beverage product quality and safety.

- Mixing and heating system:

- This prepares ingredients like sugar, water, flavors, and syrups. Components are carefully combined through precise balancers determining flow rates and liquid ratios to create complete mixtures.

- Mixers are designed with modern technology ensuring uniform mixing cycles and precise execution.

- Heated cooking or pasteurization (for fruit syrups) is commonly applied to ensure hygiene and dissolve ingredients. This system is essential for tea and herbal beverage lines.

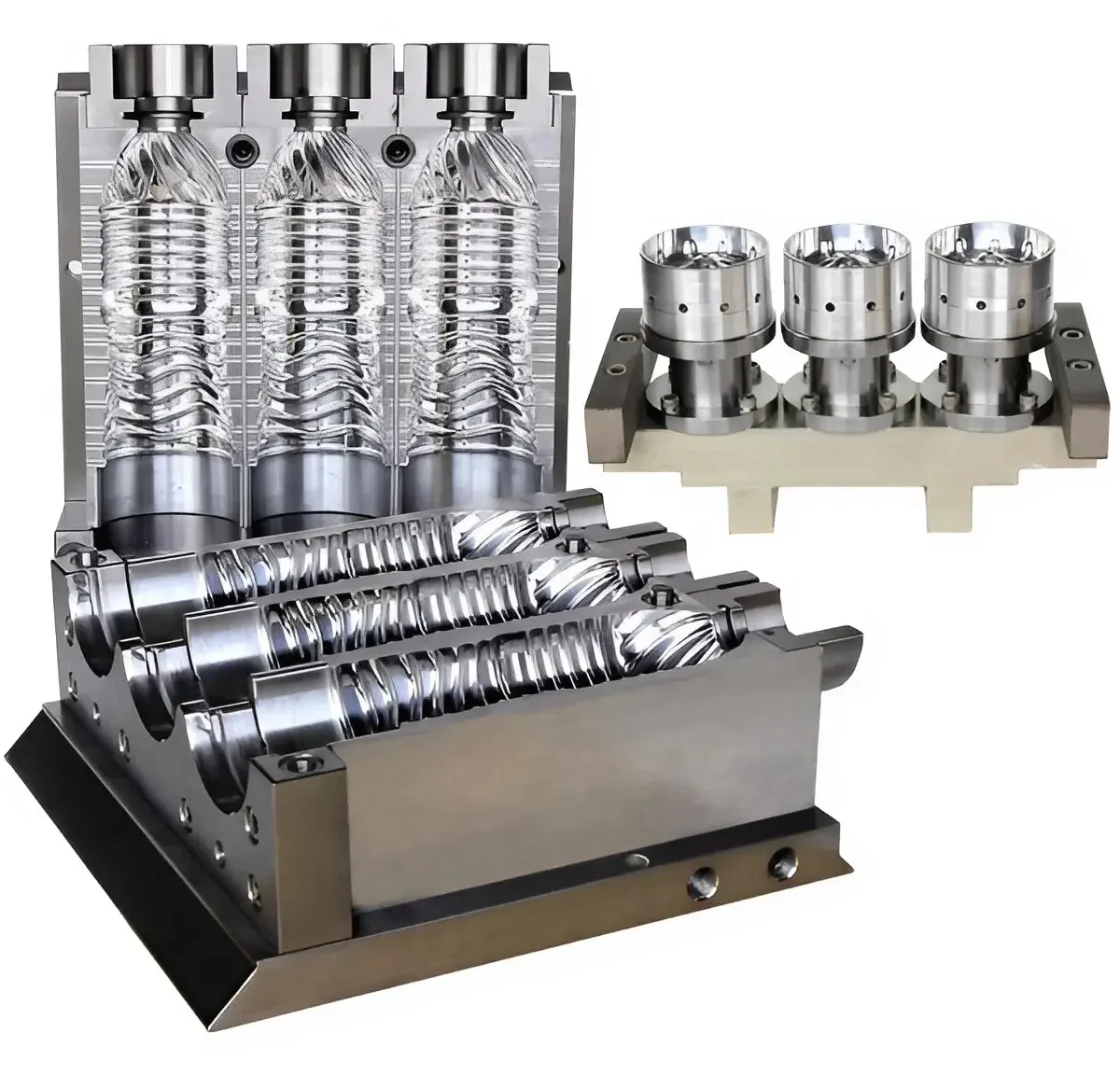

- Bottle blowers (for PET bottles):

- In-house bottle blowing offers major benefits in controlling input materials and PET bottle quality/appearance.

- Structure includes blowers (creating high pressure to blow plastic preforms), chillers (dehumidifying, drying), air filters (purifying air), air coolers, and molds for final bottle shaping.

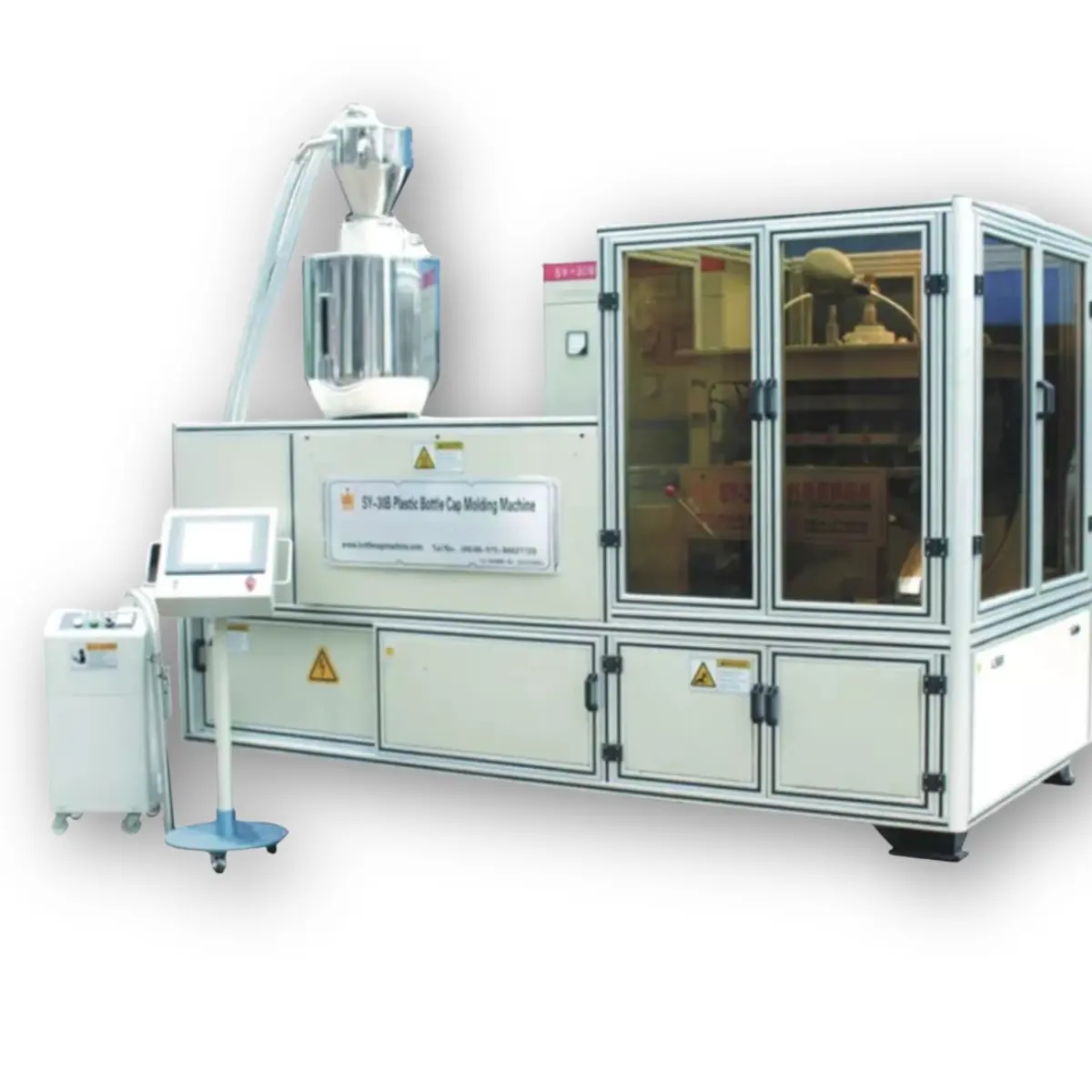

- Automatic filling and capping system:

- Structure: Automatic filling cappers typically include 02 filling heads, ingredient tanks, cap feeders, 01 capping head, and supporting machinery for smooth operation. Some systems integrate 3-in-1 functions: Wash-Fill-Cap.

- Operating principles:

- Atmospheric pressure filling (Gravity): Uses height differential between filler nozzles and bottles for natural liquid flow. Suitable for non-carbonated liquids like cooking oil, shampoo.

- Vacuum filling: After cleaning, bottles enter vacuum systems. Pressure differentials between bottles and tanks cause liquid inflow.

- Isobaric filling: For carbonated drinks. CO2 is injected into bottles until internal pressure balances with tank pressure, then liquid flows in using height advantage.

- Advantages: Completely replaces manual filling, saves labor, multiplies productivity, extreme precision (estimated error ≤5ml), stable operation, minimal errors, and easy integration into smart automated packaging lines.

- Operation process: Products are pumped/sucked/gravity-fed into tanks → Solenoid valves open, product flows through nozzles at set rates → Conveyors move containers under nozzles → Products fill containers → Upon reaching desired volume, valves close → Conveyors remove containers, preparing for next batch.

- Sterilization system:

- Purpose: Disinfecting and sterilizing products ensures food safety and extends shelf life.

- Common methods: Pasteurization (typically for juices, syrups), heat sterilization, or UHT (Ultra High Temperature) for longer shelf life. UV lamps and ozone can also sterilize water.

- For juices, sterilization is crucial after extraction and filtering to deactivate enzymes and reduce bacteria.

- Final packaging system:

- Labeling: Label applicators attach labels to bottle bodies/necks, preventing dust, enhancing product quality/aesthetics, and reinforcing branding. Automatic labelers connect with fillers/cappers via conveyors, applying 40-100 labels/minute.

- Date printing: Date printers mark production dates and expiration dates on packaging.

- Shrink-wrapping/Primary packaging: Bottle wrappers are crucial packaging line steps before carton sealing. Common shrink films like POF, PP, PE, PVC can be flexibly used.

- Boxing: Finally, containers are packed into cartons or trays, then transported via pallets/larger containers to distributors.

- Conveyor and automated transport system:

- Essential components move products between stations where machines or workers perform processes.

- Includes straight, curved, and inclined conveyors with good accumulation capabilities, mainly for transporting glass/plastic bottles.

- Conveyor systems reduce inter-process transport time, increasing output.

B. Detailed Operation Process (Example: Carbonated Soft Drink Production)

Carbonated soft drink production exemplifies technology and equipment integration in automated lines:

- Step 1: Water purification. Input water (typically from wells) undergoes coarse filtration, then sand filtration to remove fine particles. Water is chlorinated then filtered through activated carbon to remove residual chlorine/organics. Vacuum pumps degas water before entering dosing stations.

- Step 2: Heating and ingredient mixing. Prepares sugar/water ingredients. For fruit syrups, pasteurization is typically applied. Water and syrup are carefully combined via precise balancers to create complete mixtures.

- Step 3: CO2 saturation. Injects food-grade pure liquid CO2 into carbonated drinks, reaching specified concentrations. This enhances digestion and extends shelf life.

- Step 4: Filling and capping. Bottles/cans are prepared (rinsed if new, thoroughly cleaned if reused). They’re conveyed to automatic fillers. For carbonated drinks, isobaric filling principles apply. After filling, caps are automatically tightened.

- Step 5: Finishing and packaging. Filled/capped bottles undergo quality inspection (QC), then pass through date printers marking expiration dates on caps. Bottles receive body/neck labels and automatically transfer to shrink tunnel dryers. Finally, products are shrink-wrapped and boxed, ready for storage/distribution.

Automation is pivotal in ensuring continuity, precision, uniformity, and high speed throughout. It significantly reduces human intervention, limits error risks, and optimizes overall efficiency from raw material processing to final packaging.

Overall line efficiency depends not just on individual machine speeds but also on harmonious, continuous coordination between processes. Reducing downtime and shortening inter-process transport time are crucial. This highlights the importance of identifying/eliminating bottlenecks and balancing module capacities for maximum efficiency. Businesses need holistic views of product/information flows, requiring comprehensive production analysis using simulation/flow analysis tools to identify/eliminate weaknesses, ensuring no process is overloaded or excessively waiting, thereby optimizing throughput and efficiency.

Line customizability and flexibility are other key factors. Line capacity can be manufactured per customer requirements, and automation levels customized. Bottle-type change parts are also available for product diversification. This shows beverage production lines aren’t fixed solutions but highly customizable. They can be significantly adjusted to meet specific business needs regarding production scale, product types, and desired automation levels. Businesses, especially startups or expanding enterprises, should seek suppliers offering modular, flexible line designs. Future expandability/adjustability to produce different beverages or change packaging sizes will optimize initial investments and ensure rapid adaptation to market/business developments.

Table 2: Key Stages and Corresponding Equipment in Beverage Production Lines

| Key Stage | Corresponding Equipment | Primary Purpose |

|---|---|---|

| Water Treatment | Industrial RO filtration system (including coarse filters, activated carbon, softeners, RO membranes, UV/ozone) | Ensure input water meets food safety standards |

| Mixing/Heating | Tanks & Mixers | Dissolve/mix ingredients per formula, ensure uniformity |

| Bottle Blowing (if applicable) | PET bottle blowers | Shape plastic bottles from preforms, control packaging supply |

| Filling | Automatic fillers | Precisely fill products into packaging |

| Capping | Automatic cappers | Seal products for preservation and leak prevention |

| Sterilization | Sterilization systems (UHT/Pasteurization/UV/Ozone) | Kill bacteria and extend product shelf life |

| Labeling | Automatic labelers | Attach brand/product information, enhance aesthetics |

| Date Printing | Date printers | Record production/expiration information |

| Shrink-wrapping/Primary Packaging | Shrink wrappers | Protect products and create grouped packaging |

| Boxing/Secondary Packaging | Carton sealers | Complete packaging for transport/storage |

| Transport | Conveyor systems | Move products between processes continuously and efficiently |

V. Mandatory Food Safety and Quality Standards

Compliance with food safety and quality standards is vital for beverage manufacturers, not just to protect consumer health but also to ensure business reputation and competitiveness in domestic and international markets.

ISO 22000: Global food safety management system

- ISO 22000 is an international standard for food safety management systems, developed by the International Organization for Standardization (ISO). Based on HACCP hygiene management methods and Codex Alimentarius application steps, combined with prerequisite programs. Its primary purpose is helping businesses identify/control food safety hazards, minimize risks, and realize safe food supply chains from farm to table.

- ISO 22000 applies to all manufacturers and organizations in food chains, including equipment/ingredient suppliers, packaging material providers, sanitation/transport/storage services. ISO 22000 certification has international validity, facilitating global exports and consumer trust. The current version is ISO 22000:2018. Although voluntary, it qualifies to replace mandatory Food Hygiene Safety Certificates (ATVSTP) in Vietnam.

HACCP: Hazard Analysis and Critical Control Points

- HACCP is a food hygiene management system focusing on hazard analysis and identifying critical control points in production. Widely applied in food processing worldwide. HACCP is core to ISO 22000. Like ISO 22000, it’s voluntary but can replace mandatory ATVSTP certificates in Vietnam.

National regulations and standards (e.g., Vietnam Ministry of Health)

- In Vietnam, finished water products from purified water production lines must meet direct drinking water standards (6-1:2010/BYT). Establishing bottled water production facilities requires compliance with Food Hygiene Safety standards per regulations. ATVSTP certificates are mandatory for businesses manufacturing food products and/or operating catering services in Vietnam.

Compliance importance for quality assurance and export capability

- Complying with standards like ISO 22000 and HACCP not only ensures consumer safety but also enhances business reputation, branding, and market competitiveness. This expands access to international markets requiring strict food safety certifications. Continuous quality control—from inspecting raw materials before mixing to meticulously monitoring all tanks, pumps, and containers—is essential to prevent bacterial growth and ensure highest final product quality.

VI. Conclusion and Recommendations

Modern beverage production lines have evolved from mere machine collections into integrated production ecosystems where components are interconnected, centrally controlled, and managed to optimize entire systems. This transformation delivers superior benefits in productivity, consistent product quality, cost optimization, labor safety, food hygiene, and enhanced market competitiveness/adaptability.

Although automation investments in beverage production entail high initial costs, they represent strategic investments yielding significant long-term economic benefits. Beyond reducing labor costs and material waste, they elevate workforce expertise, creating adaptable, skilled labor pools. For maximum efficiency, businesses need holistic process views, identifying/eliminating bottlenecks, and balancing module capacities. Moreover, modern lines’ customizability and modularity enable flexible product/production scale adjustments, responding swiftly to market trends and new opportunities.

To optimize beverage production line investments/operations, these strategic recommendations are proposed:

- Adopt integrated production ecosystem thinking: Rather than focusing on individual machines, businesses should consider equipment/software integration, compatibility, and synchronization. The goal is optimizing entire production system performance from raw material processing to final packaging.

- Invest simultaneously in technology and people: Alongside automated line implementation, develop personnel training/development strategies. Transitioning labor roles from manual to operating, monitoring, and maintaining complex systems maximizes automation benefits and creates adaptable, skilled workforces.

- Evaluate costs via Total Cost of Ownership (TCO): When making investment decisions, look beyond initial purchase costs to analyze TCO and overall economic benefits throughout equipment lifecycles. Initial investments aren’t mere expenses but financial levers optimizing entire production value chains.

- Prioritize modularity and flexibility in line design: Choose suppliers capable of advising/designing lines allowing easy expansion/adjustment to produce different beverages or change packaging sizes. This optimizes initial capital investments and ensures adaptability to market/business developments.

- Implement continuous process optimization: Thoroughly analyze product/information flows to identify/eliminate bottlenecks. Ensure no processes are overloaded or excessively waiting, optimizing overall line throughput and efficiency.

- Strictly comply with food safety standards: Ensure lines/production processes comply with international standards (ISO 22000, HACCP) and national regulations (e.g., Vietnam Ministry of Health standards). This isn’t just legal compliance but key to building consumer trust, enhancing brand reputation, and expanding global export opportunities.

VII. Reference Pricing and Technical Support

We provide diverse solutions at competitive prices:

| Line Type | Capacity | Reference Price (VND) |

|---|---|---|

| PET bottled water | 1000L/h | From 350 million |

| Tea – fruit juice | 2000L/h | From 680 million |

| Carbonated drinks | 3000L/h | From 950 million |

💡 Technical support: We provide free surveying, layout consulting, design drawings, installation, and 12-24 month warranties.

VIII. Why Choose [Your Company Name]?

With over a decade of experience and dedication, [Your Company Name] proudly serves as your trusted partner:

- 10+ years experience successfully implementing 500+ water plants nationwide.

- Expert engineering team, professionally trained in food industry.

- Comprehensive A-Z solution consulting, ensuring all project aspects.

- Long-term warranty commitment with readily available spare parts ensuring continuous operation.

- Notable clients: Lavie, Bidrico, Khanh Hoa Bird’s Nest, and other leading enterprises.

IX. Frequently Asked Questions (FAQ)

1. Can lines be customized for specific beverage types?

Yes. We design according to customer requirements, suitable for specialized beverages like soft drinks, alkaline ion water, juices, green tea, bird’s nest drinks, etc.

2. How long does installation and handover take?

Installation/handover typically takes 7-30 days, depending on line scale/configuration.

3. Do lines require periodic maintenance?

Yes. We provide 3-6 month maintenance services with 24/7 technical hotlines.

4. Do you provide ingredients or processing formulas?

We partner with premium flavoring/additive suppliers and offer free R&D formula support for new product development.

X. Register for Consultation and Pricing

🎯 Seeking modern, affordable, easy-to-operate beverage production lines?

➡ Contact us immediately for:

Free customized consultations. Detailed quotes & line layout drawings. 📞 Hotline: (028) 888 333 88 📧 Email: sale@nghitin.net 🌐 Website: www.nghitin.net 🏡 Address: 8bis, National Highway 13, Binh Hoa Ward, Lai Thieu, Thuan An City, Binh Duong ProvinceDon’t miss opportunities to elevate your production operations!

Reviews

There are no reviews yet.