Construct an energy-saving gas station and supply air compressors.

An air compressor is a device that converts mechanical energy into compressed air energy, supplying high-pressure air for various industrial and residential applications.

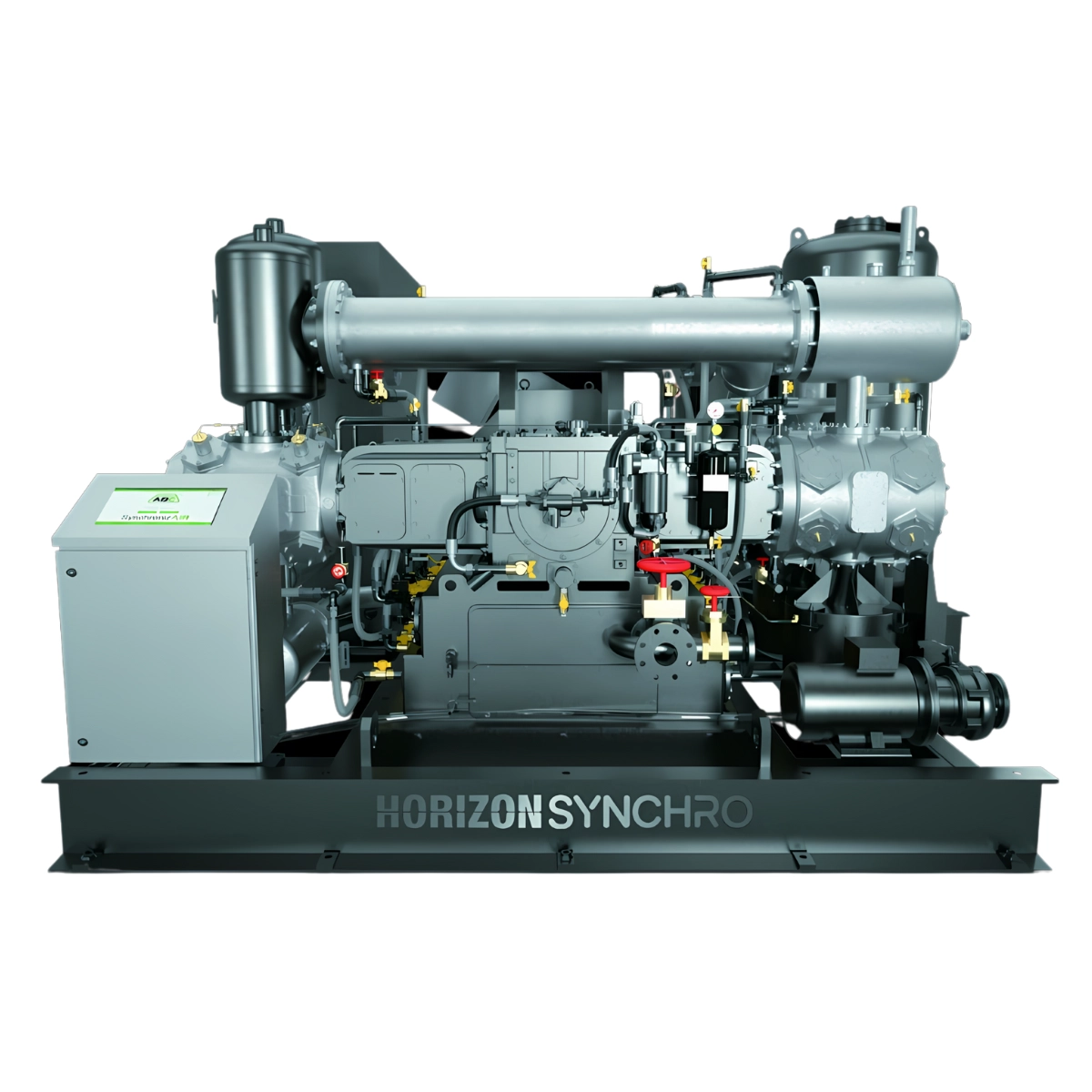

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

Air Compressor

In the modern industrial world, air compressors play an indispensable role, providing clean and efficient energy for numerous production and operational processes.

What is an Air Compressor?

To truly understand the role and importance of air compressors, we need to delve into their definition, common types, and basic structure. An air compressor is not just a machine that generates pressure—it’s a complex system designed to convert electrical or mechanical energy into potential energy in the form of compressed air, ready to serve countless applications.

Definition of an Air Compressor

An air compressor can be defined as a mechanical device designed to convert energy. Specifically, it draws in gas from the surrounding environment (typically air) and reduces its volume, thereby increasing its pressure. This process produces compressed air, a versatile energy source that can be stored in tanks and used for various purposes. This is the core answer to the question: What is an air compressor?

- Compressed air is a clean energy source. Unlike fossil fuels, using compressed air does not produce harmful emissions at the point of use, making it an environmentally friendly choice for many applications, especially in industries requiring cleanliness, such as healthcare, food processing, and pharmaceuticals.

- Versatility is one of its greatest benefits. Compressed air can power pneumatic tools, automate control systems, clean surfaces, paint, package products, and even provide breathable air for divers or firefighters. This wide range of applications makes the air compressor essential in most industries.

- Technically, the compression process follows fundamental physics principles, primarily Boyle-Mariotte’s Law, which states that at a constant temperature, the pressure of a given gas is inversely proportional to its volume. Air compressors use various mechanisms to reduce gas volume, thereby increasing pressure to the desired level. Understanding this principle is key to selecting and operating an air compressor efficiently.

- In the context of industrial air compressors, this definition expands to include high-capacity systems designed for continuous operation in demanding production environments. Industrial air compressors often feature complex designs, integrating cooling, filtration, and drying systems to ensure the highest air quality for specialized applications.

Types of Air Compressors

Air compressors are classified based on various criteria, including operating principles, design, applications, and capacity. Understanding these types helps users select the most suitable equipment for their needs.

- Based on operating principles:

- Piston (Reciprocating) Air Compressors: The most traditional type, using pistons moving within cylinders to compress air. They are simple, easy to maintain, and ideal for high-pressure, low-flow applications like small workshops or automotive garages.

- Rotary Screw Air Compressors: Use two interlocking helical screws for compression. These are efficient, quiet, and stable, making them popular for industrial air compressors requiring continuous operation.

- Centrifugal Air Compressors: Utilize high-speed impellers to convert kinetic energy into pressure. Suitable for large-scale applications like chemical plants or HVAC systems.

- Based on design:

- Oil-Free Air Compressors: Deliver 100% oil-free air, critical for medical, pharmaceutical, and food industries.

- Oil-Lubricated Air Compressors: Use oil for cooling and sealing, common in general industrial applications.

- Based on application:

- Portable Air Compressors: Small, mobile units for tasks like tire inflation or DIY projects.

- Industrial Air Compressors: Heavy-duty systems for factories and large-scale production.

Basic Structure of an Air Compressor

Though designs vary, most air compressors share core components ensuring intake, compression, and output functions. Understanding this structure aids in maintenance and troubleshooting.

- Motor/Engine: Powers the compression mechanism (electric or fuel-driven).

- Compression Chamber: The "heart" of the compressor (pistons, screws, or impellers depending on type).

- Air Receiver Tank: Stores compressed air to stabilize pressure and reduce cycling.

- Control System: Includes pressure switches, sensors, and safety valves.

- Cooling System: Dissipates heat generated during compression.

- Filtration System: Removes contaminants for clean air output.

How Air Compressors Work

Understanding what an air compressor is and its structure is just the beginning. Efficient operation and maintenance require knowledge of its working principles—a scientific process influenced by external factors and strict safety protocols.

Compression Process

The compression cycle involves carefully calculated steps from air intake to storage. While mechanisms differ by type, all compressors reduce volume to increase pressure.

- Air Intake: Ambient air is drawn through an inlet filter.

- Compression: Volume reduction via pistons, screws, or impellers.

- Cooling: Hot compressed air passes through intercoolers.

- Moisture Separation: Condensed water is removed via drains or dryers.

- Storage: Air is held in tanks at regulated pressure.

- Distribution: Delivered through piping to end-use equipment.

Performance Factors

Efficiency depends on both the machine and external conditions. Optimizing these saves energy and extends equipment life.

- Inlet Air Quality: Dirty/humid air reduces efficiency.

- Operating Pressure: Higher pressure = higher energy use (7% more per 1 bar).

- Ambient Temperature: Affects cooling capability.

- Maintenance: Regular servicing prevents energy waste.

- Air Leaks: A small leak can waste thousands of kWh annually.

- Lubricant Quality: Critical for oil-lubricated models.

Safety Considerations

High-pressure systems demand strict safety measures during operation and maintenance.

- Tank Explosion Risk: Requires regular inspections and safety valves.

- High-Pressure Hazards: Ruptured lines can cause injuries.

- Electrical Risks: Proper grounding is essential.

- Burn Hazards: Hot components during/after operation.

- Noise Exposure: Hearing protection for loud models.

- Contaminated Air: Filtration is critical for breathing air.

Applications of Air Compressors

The versatility of compressed air makes air compressors indispensable across industries. From simple tasks to complex automation, compressed air plays a vital role. Understanding these applications highlights why air compressors are essential and helps select the right system.

In Manufacturing

- Material handling via pneumatic conveying

- Packaging and sealing machinery

- Cleaning production equipment

- Automation controls (pneumatic cylinders/robotics)

- Creating inert atmospheres for sensitive processes

- Precision assembly in electronics/pharma

In Construction

- Powering jackhammers, nail guns, sandblasters

- Spraying concrete (shotcrete)

- Cleaning surfaces before finishing

- Operating heavy machinery controls

- Supplying breathable air in confined spaces

- Pressure testing pipelines

In Healthcare

- Medical ventilators for respiratory therapy

- Surgical tools (dental drills, bone saws)

- Central hospital air systems (ORs, ICUs)

- Nebulizers for aerosol medication

- Laboratory sample transport

Other Industries

- Automotive: Tire inflation, paint sprayers

- Printing: Press operation/cleaning

- Textiles: Weaving/loom machinery

- Mining: Rock drills/ventilation

- Transport: Air brakes (trucks/trains)

- Aviation: Aircraft assembly/maintenance

- Diving: Scuba tank filling

- Entertainment: Inflatable attractions/effects

- Home Use: DIY tools/tire inflation

Benefits of Using Air Compressors

Investing in air compressor systems offers significant advantages—optimizing production, improving product quality, and reducing long-term costs. This explains why industrial air compressors are indispensable in modern facilities.

Time & Cost Savings

- Faster operation vs manual/electric tools

- Reduced labor costs through automation

- Lower energy costs in centralized systems

- Longer tool lifespan (fewer moving parts)

- Minimized downtime with proper maintenance

Productivity Gains

- Multiple tools operating simultaneously

- Quick changeovers between tasks

- Continuous operation in harsh conditions

- Reduced worker fatigue (less vibration)

- Consistent output quality

Quality Assurance

- Oil-free air for contamination-sensitive processes

- Precise pressure control for uniform results

- Dry air prevents product spoilage

- Consistent spray painting finishes

- Leak testing for quality control

Choosing an Air Compressor

Selecting the right air compressor critically impacts operational efficiency, costs, and equipment longevity. Multiple factors must be considered—from usage needs to maintenance planning.

Assessing Requirements

- Pressure Needs (PSI/bar): Highest tool requirement + 10-20% buffer

- Airflow (CFM/liters/min): Total simultaneous demand

- Duty Cycle: Continuous (screw) vs intermittent (piston) use

- Air Quality: Oil-free for sensitive applications

- Environment: Temperature/space considerations

- Budget: Total cost of ownership (not just purchase price)

Selecting the Right Type

- Piston: High pressure, low flow, intermittent

- Screw: Continuous, high-volume industrial use

- Centrifugal: Very high volume, lower pressure

- Oil-Free vs Lubricated: Based on air purity needs

- Portable: Jobsite mobility with gas engines

Maintenance Best Practices

- Follow manufacturer service schedules

- Daily checks: oil levels, unusual noises

- Use genuine replacement parts

- Proper lubricant selection/replacement

- Regular filter/dryer maintenance

- Leak detection programs

- Keep units clean/ventilated

Conclusion

The air compressor is a pivotal mechanical device in modern industry—transforming energy into versatile compressed air. Its diverse designs (from simple pistons to complex screw systems) operate on precise physical principles, influenced by intake quality, pressure needs, and environmental factors. Applications span manufacturing, construction, healthcare, and beyond, each with unique air quality requirements. Benefits include time/cost savings, productivity gains, and quality assurance, especially with industrial air compressors. Proper selection based on needs, type, and maintenance ensures safety and optimizes performance. Ultimately, understanding what air compressors are and their operational principles helps businesses achieve sustainable growth.